3" x 3" x 0.375" Aluminum T-Bar 6061-T6-Extruded

With dimensions of 3" x 3" x 0.375", this Aluminum T-Bar is made from 6061-T6 extruded aluminum, providing a strong yet lightweight solution for structural applications. The extrusion process gives it the desired T-shaped cross-section, and the T6 heat treatment increases its strength and stress resistance. The 0.375" thickness adds additional strength, making this T-bar suitable for heavier-duty applications where additional load-bearing capacity is required. It is commonly used in industries like construction, aerospace, and machinery, where high strength and durability are essential.

This material meets the following specs: AMS-QQ-A-200/8, ASTM-B221, ASTM-B308

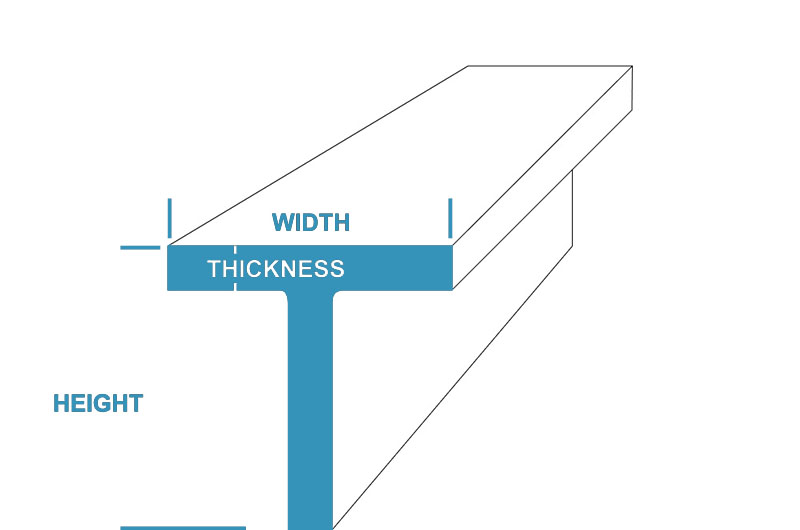

3" x 3" x 0.375" Aluminum T-Bar 6061-T6-Extruded Specifications

| Specification | Details |

| Height | 3" |

| Thickness | 0.375" |

| Width | 3" |

| Material | Aluminum |

| Form | t bar |

| Alloy Type | 6061 |

| Max Length | 300 inches |

| Temper | T6 |

| Production Method | Extruded |

3" x 3" x 0.375" Aluminum T-Bar 6061-T6-Extruded More Informations

Characteristics:

- Weight and Strength Balance: This size offers a high strength-to-weight ratio, suitable for high-load applications while maintaining a lightweight profile.

- Fatigue Resistance: This T-bar size is particularly suitable for long-term load-bearing applications due to its excellent fatigue resistance.

- Machining: Good machinability for cutting, drilling, and shaping, with excellent surface treatment options.

Applications:

- Structural Applications: Commonly used in bridges, heavy equipment supports, and industrial structures.

- Automotive: Used for larger automobile frames, support structures, and body components.

- Aerospace: Suitable for structural components requiring high strength, such as wing supports and aircraft brackets.

- Industrial Equipment: Frequently used for frames and support parts in industrial machinery.

Processing:

- Extrusion & Customization: Precision extrusion allows for tailored cuts and custom machining to meet specific design needs.

- Heat Treatment: The T6 heat treatment process increases the strength of this T-bar, making it suitable for high-performance applications.

Different sizes of 6061-T6 aluminum T-bars are widely used in aviation, automotive, industrial, construction and other fields due to their superior mechanical properties, good weldability, excellent corrosion resistance and high strength. T-bars of different sizes are suitable for various needs from light structures to heavy load-bearing applications, and all of these products are heat treated to achieve higher strength, enabling them to withstand higher loads. In terms of processing, 6061-T6 aluminum has good operability in extrusion and subsequent processing, which is convenient for meeting various customized needs.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

6061 T6 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 95 |

| Ultimate Tensile Strength KSI | 45 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 60 |

| Machinability % | 50 |

| Melting Point °F | 1080 - 1205 |

| Electrical Conductivity % IACS | 43 |

| Shear Strength KSI | 30 |

Chemistry Information 6061 Aluminum

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |