0.875" Aluminum Hexagonal Bar 2024-T351-Cold Finish

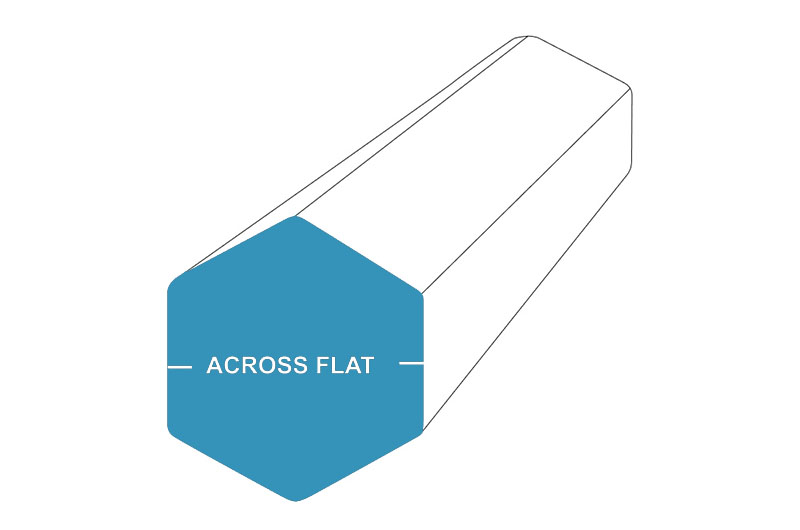

The 0.875-inch hexagonal aluminum bar is manufactured using 2024 alloy in T351 temper and cold-finished for exceptional surface quality and dimensional accuracy. With its "across flats" measurement, this bar is ideal for use in demanding environments, including aircraft structure components, mechanical couplings, and heavy-duty assemblies.

0.875" Aluminum Hexagonal Bar 2024-T351-Cold Finish Specifications

| Specification | Details |

| Across Flats | 0.875" |

| Material | Aluminum |

| Form | hexagonal bar |

| Alloy Type | 2024 |

| Max Length | 300 inches |

| Temper | T351 |

| Production Method | Cold Finished |

0.875" Aluminum Hexagonal Bar 2024-T351 - Cold Finish More Informations

Features:

- High strength, excellent fatigue limit, suitable for long-term high-load use.

- Moderate corrosion resistance.

- High machinability, allowing for complex processing.

Applications:

- Supports and wing components for aircraft.

- Hexagonal fasteners in transportation and engineering equipment.

- Assembly parts requiring high load and strength.

Processing Method (Cold Finish):

- Cold drawing provides a polished surface and tight tolerances.

- Enhanced surface hardness improves wear resistance.

Select length below or Custom Cut

- 12" (1 ft.)

- 24" (2 ft.)

- 36" (3 ft.)

- 48" (4 ft.)

- 72" (6 ft.)

- 96" (8 ft.)

- 144" (12 ft.)

- 192" (16 ft.)

- 240" (20 ft.)

- 288" (24 ft.)

- 300" (25 ft.)

- Custom cuts supported

2024 T351 Aluminum Material Data Sheet

| Physical Properties | Metric | English | Comments |

| Density | 2.78 g/cc | 0.1 lb/in³ | AA; Typical |

| Mechanical Properties | |||

| Hardness, Brinell | 120 | 120 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 150 | 150 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 46.8 | 46.8 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 75 | 75 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 137 | 137 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 469 MPa | 68000 psi | AA; Typical |

| Tensile Yield Strength | 324 MPa | 47000 psi | AA; Typical |

| Elongation at Break | 19 % | 19 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Elongation at Break | 20 % | 20 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Modulus of Elasticity | 73.1 GPa | 10600 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Ultimate Bearing Strength | 814 MPa | 118000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 441 MPa | 64000 psi | Edge distance/pin diameter = 2.0 |

| Poisson's Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 138 MPa | 20000 psi | AA; 500, 000, 000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 26 MPa-m½ | 23.7 ksi-in½ | K(IC) in S-L Direction |

| Fracture Toughness | 32 MPa-m½ | 29.1 ksi-in½ | K(IC) in T-L Direction |

| Fracture Toughness | 37 MPa-m½ | 33.7 ksi-in½ | K(IC) in L-T Direction |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 28 GPa | 4060 ksi | |

| Shear Strength | 283 MPa | 41000 psi | AA; Typical |

| Electrical Properties | |||

| Electrical Resistivity | 5.82e-006 ohm-cm | 5.82e-006 ohm-cm | AA; Typical at 68°F |

| Thermal Properties | |||

| CTE, linear 68°F | 23.2 µm/m-°C | 12.9 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.7 µm/m-°C | 13.7 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.875 J/g-°C | 0.209 BTU/lb-°F | |

| Thermal Conductivity | 121 W/m-K | 840 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 502 - 638 °C | 935 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 502 °C | 935 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 256 °C | 493 °F | |

Chemistry Information 2024 Aluminum

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | - | 0.15 | GB/AMS/EN |